Treatment plant

General information

Process description

Fig. 1. The area of the Sewage Treatment Plant "Czułów Sp. z o.o."

The area on which the treatment plant is located belonged to Śląskie Zakłady Papiernicze (currently TOP S.A.). It was an industrial, undeveloped site on which no activities were carried out. In 1988, the construction of the treatment plant for the then Silesian Paper Mills began. The construction of the facilities lasted until 1997, when, as a result of the transformation, a company was established with the participation of a French investor under the name of OTOR Silesia S.A. In June 1998, by Notarial Deed No. 8715/98, a company named Wastewater Treatment Plant Czułów Sp. z o.o. was established with the participation of OTOR Silesia S.A. and the Tychy Municipality.

Following the establishment of the Company, construction resumed and in November the first line was put into operation to receive paper sewage. The built facilities were contributed in kind to the Company and the task of the Company was to treat the wastewater. By making a cash contribution to the Company's capital, Tychy Municipality undertook to divert domestic sewage from the northern part of the city of Tychy to the treatment plant. The target volume of this wastewater was to be 1200 m3/day. The inflow of such a large volume of social sewage was desirable for technological reasons. This meant supplying phosphorus and nitrogen in sufficient quantities for a properly conducted treatment process. Unfortunately, the shareholder, the Municipality of Tychy, obtained EU funds and directed all municipal wastewater, with the exception of the Osada district, to the municipal treatment plant in Tychy-Urbanowice, The consequence is the use of nutrients (ammonium phosphate) at the treatment plant, which supply phosphorus and nitrogen.

Rys. 2. Odpływ oczyszczonych ścieków do odbiornika Rzeki Mlecznej.

In July 2007, OTOR Silesia S.A sold its shares in the treatment plant to TOP S.A. Currently, in the company Oczyszczalnia Ścieków Czułów Sp. z o.o. TOP S.A. holds 80.5% of the shares and the Municipality of Tychy holds 19.5%.

According to a copy of the National Court Register, the object of activities of the Czułów Wastewater Treatment Plant is: 37.00.Z - provision of sewage disposal services.

The WWTP does not carry out any production activities, but only treats wastewater from the TOP S.A. plant, sewage and its own wastewater. Its maximum wastewater flow capacity is 3 510m3/day, i.e. the treatment plant is capable of treating 1 281 150m3 of wastewater/year. Their degree of treatment complies with both national and EU requirements (Fig.1.).

Fig. 3. Bioreactor, the heart of the treatment plant.

Fig. 4. Famet station for mechanical wastewater treatment and dewatering press

Domestic and boiler wastewater from TOP S.A. flows by gravity to the mechanical wastewater treatment station (Fig. 4.) and is then fed by pumps into the mixing chamber and the distribution chamber before the aeration chamber.

Post-production wastewater from TOP S.A., after passing through the mechanical part (grille, Dorr settling tank), flows into the mixing chamber and then onto the aeration chamber (Fig. 3.). The mixing chamber also receives rainwater and snowmelt, domestic and process water from the treatment plant area, supernatant water from WKFs, recycled sludge from secondary settling tanks and nutrient solutions are dosed. In the aeration chamber, the biological wastewater treatment process takes place using the highly loaded activated sludge method (Figure 5). The wastewater is characterised by low concentrations of nitrogen and phosphorus compounds. Ammonium phosphate is used to balance these compounds. Phosphorus is chemically precipitated with a 42% aqueous solution of ferrous sulphate Fe2(SO4)3 - PIX 113, dosed before the secondary settling tank. Periodically, the sludge structure-changing filamentous bacteria inhibitor PAX 18 (aluminium polychloride) is dosed into the aeration chamber.

After the aeration chamber, the wastewater flows into a distribution chamber and then into the secondary settling tank (Figure 6), where the activated sludge and wastewater are separated.

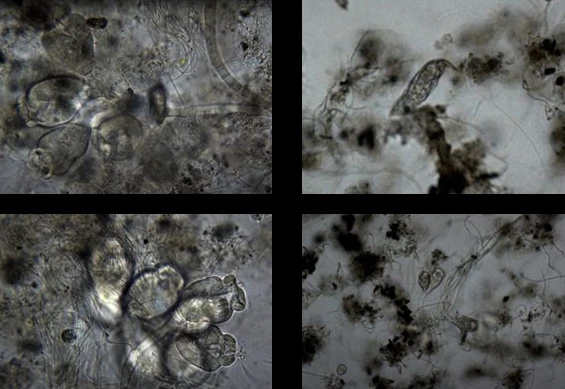

Fig. 5 Pictures of activated sludge taken with the MikroCam 3.0MP camera

Fig. 6 Secondary settling tank.

The sludge is raked into the sludge hopper and recirculated to the aeration chamber or, as surplus sludge, directed to the digesters (Fig. 7), where the sludge is treated by anaerobic decomposition of organic matter. The surplus sludge water from the digesters is returned to the aeration chamber. The sludge from the digesters, after being dewatered on a mobile press, is collected by an external company.

Fig. 7 One of the two digesters

In order to increase the capacity of the existing wastewater treatment facilities without expansion, liquid oxygen technology was used. Depending on the demand for oxygen, it can be supplied in liquid form - transport by tanker trucks to storage tanks. By using liquid oxygen, the efficiency of the process can be increased by oxidising chemicals. The pure oxygen system is of a supportive nature, and can be used when maximum loads occur by activating an oxygen dosing system directly into the activated sludge chamber (Figure 8).

The system consists of: a specialised cryogenic gas storage tank, an evaporator and a dosing system.

The treated effluent from the secondary settling tank is directed to the Milk River via an outflow trough.

Fig. 8: Liquid oxygen dosing installation.